|

Hooked on Felting Part 1

|

Funky

My first needle felted bear “Funky”.

|

By Neysa A. Phillippi

Needle felting is the latest craze in the ted dy bear world. Felting in one form

or another has been around since the cave man first put mammoth wool in his foot coverings.

Moisture from his feet and the friction

of walking “felted” the wool, which then became a great padding that was water repellent and warm.

“Wet felting” is the process of moisture

or water, friction and heat. When wet felting, wool is worked until the natural “barbs” in the wool open and lock, “felting” the wool fibers together.

I personally have been needle felting since July 2003. After 21 years making bears and other animals, felting has consumed me but has been a refreshing

change.

|

Ike before felting |

|

Ike during felting |

|

Ike after felting |

|

Ike’s foot pads |

|

“Duddy the Rat” mohair/felted head |

|

“Bart” Example of mohair with felting

|

Sewing bears 14 hours a day, seven days a week

for 20 plus years, tends to get old. I love creating and so much sewing limited my creative time.

When I became a teddy bear artist, I thought that

I had realized my dream of being what I wanted

to be when I grew up. Needle felting and writing have pushed me beyond what I thought was the limit of my abilities.

My passion for needle felting began when Becca Bednarz, Maplewood’s Treasures, gave me one

little wad of black wool batt.

Thanks to Becca, I have a fresh new outlook on life

in the bear making world.

I will cover a few aspects of felting per issue in my Hooked on Felting column. Questions, comments

and your input are welcome.

Needle felting is like sculpting with clay. Each piece

I create is a one-of-a-kind and allows my creative mind to run wild.

One creation leads to another, and improvement

in techniques and designs progress rapidly for me.

I only wish I had more hours in the day.

I have also realized that felting the faces and paw pads of my mohair critters, adds more life to the animals I create from materials other than felt.

Needle felting in the form I am writing about is “dry” felting. I find this form of felting, much cleaner and the felting itself, more intense than wet felting.

The critters I felt, are two to four inches, and take about eight to 10 hours per critter.

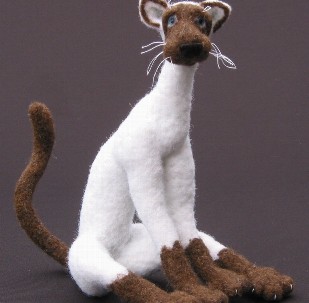

The Siamese cat pictured below, is seven inches

tall and took 36 hours to needle felt. That is

intense, especially when you get addicted to it

and work for eight or more hours straight.

|

|

“An Indy Cat”

|

“Noodle Poodle”

|

Felting is sculpting using wool batt or roving. Batt

is cleaned and carded wool; with the wool fibers

going in all directions. Roving is basically one step beyond wool batt; it is carded until all the fibers

are going in one direction. Roving is more often

used when spinning.

Carding takes place after the wool is washed and

is either accomplished with a carding machine,

|

Batt sample |

|

Roving sample |

drum or hand carders. Cleaned and carded wool

is readily available.

|

Hand carding with dog brushes |

|

Fiber being fed into

carding machine |

|

Fiber running through the carding machine |

|

Carding unit |

|

End product of the carding process |

If you want to card small lots

of wool, try using two metal

dog brushes, to work the

fibers back and forth, mixing them together.

Carding machines and even hand carders are a bit pricey, but with a carding machine, drum carders or hand carders you can mix different colors or

wools together to create your

own blend.

Felting needles come in many sizes, many more than are used in this form of felting.

Industrial felting looms use thousands of needles on a needle board. In dry felting,

|

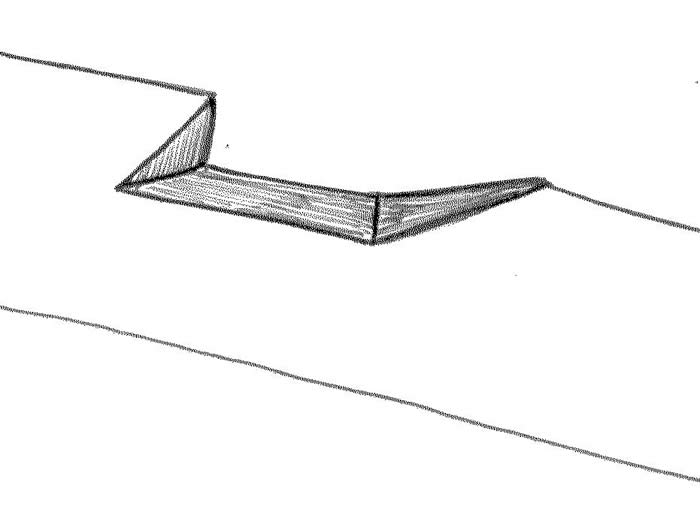

Barb or notch on needle shaft |

| |

|

Felting needle edges |

one needle is the norm.

Felting needles are straight

with barb cut along the

needle's shaft; they are

made of high gauge steel

and are sharp but brittle if

bent.

“Barbs” are cut along the needle's shaft. When the needle is poked or pushed

into the wool, the barbs pull the fibers down, locking or hooking them together.

Wool has natural “barbs” and needling it locks it together more quickly.

The felting needle’s barbs

are cut in one direction so that felting of the fibers will occur when the needle is pushed in and not when it is pulled out.

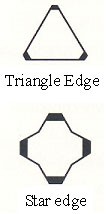

Felting needles have multiple

sides or edges; they are either triangle- or star- shaped.

The barbs on the sides of the needle push or condense to reduce the mass of wool batt, roving or polyester fiber into itself. Yes, you can even felt polyester stuffing.

The wool batting or roving will lock together and hold the fiber firmly

in place. It is almost impossible to pull the felting apart.

“T” or Triangle is the shape of the needle's tip; this needle has three

edges or sides that are flat on the shaft end in a triangular shape.

The other type of felting needle is the “S” or Star-shaped tip, which

has four edges or sides and a concave groove between the four edges.

It also has more barbs than the triangle and “needles” faster.

Felting needles are sized or gauged by the thickness and shape of the

needle - the lower the needles number the thicker the needle and the

larger the holes in the felted surface. Alternatively, the higher the needle number the finer the needle or the smaller the hole it leaves in your

creature.

Lower numbers are for the beginning

stages of felting when you are compressing and shaping the fiber. Higher nimbers for finishing - the

fine detailing at the end of construction.

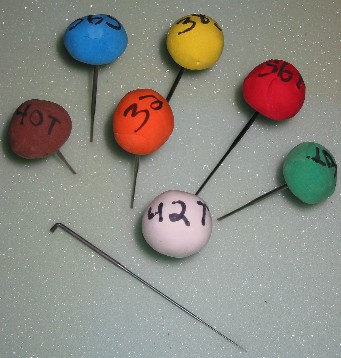

The most common needles are 36 Triangle, 36 Star, 38 Triangle, 38 Star, 40 Triangle, and 42 Triangle.

36 triangle, 36 star - a beginning needle used when starting your

project.

38 triangle, 38 star - good for detail work

40 triangle - good for fine detail work, creating a smooth surface

for your project

42 triangle - good for very fine detail and a very smooth surface,

but I believe this needle is optional for some projects.

Once hooked on felting, (believe me, once you start felting, you will

get hooked!), you may want to use a Sculpey, Fimo or Crayola Model

Magic to create a knob on the top of your needle (over the Allen key

L-shape called the "crank"). This will make the needle more comfortable

when holding it for long periods.

Wood and metal needle holders are readily available, but it is much

less expensive to use Crayola Model Magic.

When you break a needle, simple work the needle out of the modeling

clay and insert a new one, adding a touch of Elmer’s Glue and drying it,

point end up.

Once the glue sets, you can start felting again. If using Sculpey or Fimo,

you also have to replace the knob when you break a needle because

Sculpey and Fimo need to be baked in your oven.

|

Needles pictured with Sculpey heads, and one as purchased |

I keep several sets of needles, with Crayola Model Magic knobs, handy so that I can continue felting even if I break a needle.

Bobbie Ripperger, recommended I use Crayola Model Magic, which has a spongy feel when

it dries - not hard like Sculpey or Fimo.

I purchase a Deluxe Variety Pack containing nine colors, which is more reasonable than buying the colors separately.

I then label the knob with permanent markers as 36 T, 36 S, 38 T, 38 S...etc. Another option is to purchase one color of Crayola Magic, Sculpey or Fimo and label the knobs with permanent black marker.

Personally, I find reaching for a color is easier than reading needle tops.

Mine are also numbered but after working with them for a while, you recognize the needle by color.

Tools are available that hold one or several needles. I have not found

one yet that meets my needs.

WORDS OF CAUTION: please keep felting needles out of reach of children

and pets. NEVER put a needle down and just leave it. Put it back in its envelope or in a sealed container. ALWAYS put needles away, particularly

if you have children or pets. It only takes one second for a child or pet,

to grab the needle and injure themselves.

Needle felting requires your undivided attention, especially where your

fingers and eyes are concerned. The needles are made of highly tempered steel, which means they are very sharp and brittle.

Needle in and out in a straight line. Never bend the needle or use it

to pick or pry with, such as to pick out straw that is in the wool - the

needle will snap.

When you break a needle and you

will, ALWAYS find the pieces and discard

them! Wearing glasses or goggles is

a good idea.

Think about updating your tetanus shot

next time you visit the doctor since you

are working with highly tempered steel

and natural wool fibers.

45 Gorman Avenue

Indiana, PA 15701-2244 USA

Please direct comments on this article to: neysa@purelyneysa.com

Part 2 and Part 3

Home • Contact Us • Join Bears&Buds

|

3428 Hillvale Road

3428 Hillvale Road  Louisville, KY 40241 USA

Louisville, KY 40241 USA